Anyone who’s ever delved into nuclear reactor technology has likely encountered the EPOR-BWR (Economic Simplified Passive Oregon Boiling Water Reactor). This innovative reactor design represents a significant leap forward in nuclear power generation combining safety simplicity and economic efficiency.

In today’s energy landscape where sustainability meets cutting-edge technology the EPOR-BWR stands out as a beacon of progress. It’s revolutionizing how we think about nuclear power by incorporating passive safety systems that don’t require operator intervention or external power to function in emergency situations. Think of it as the self-driving car of nuclear reactors – smart safe and surprisingly straightforward.

Eporbwr

The EPORBWR represents an Economic Simplified Passive Oregon Boiling Water Reactor designed for enhanced nuclear power generation. This advanced reactor system incorporates passive safety mechanisms that function independently without operator intervention or external power sources.

Key features of the EPORBWR include:

- Natural circulation cooling that eliminates the need for recirculation pumps

- Gravity driven emergency core cooling systems

- Steam driven emergency power generation

- Containment isolation valves with passive actuation

- Simplified plant systems reducing maintenance requirements

The reactor’s specifications demonstrate its efficiency:

| Parameter | Value |

|---|---|

| Power Output | 1,500 MWe |

| Design Life | 60 years |

| Emergency Cooling | 72 hours passive |

| Core Size | 20% smaller than traditional BWRs |

| Construction Time | 36 months |

EPORBWR technology creates electricity through a direct cycle system where water boils directly in the reactor core. Steam flows upward through separators then drives the turbine generator producing power. This streamlined process eliminates the need for separate steam generators intermediate heat exchangers.

The design prioritizes three core principles:

- Economic viability through reduced operational costs

- Enhanced safety via passive protection systems

- Operational simplicity with fewer components

These innovations make the EPORBWR a distinct advancement in nuclear reactor technology compared to traditional boiling water reactor designs.

Benefits of Using an Eporbwr

The EPORBWR delivers significant operational advantages through its innovative design features. Its simplified systems create a more efficient power generation process while reducing operational complexity.

Energy Efficiency Advantages

The EPORBWR achieves a thermal efficiency rate of 34% compared to 32% in traditional BWRs through optimized steam circulation paths. Natural circulation eliminates the need for recirculation pumps, reducing parasitic power losses by 15%. The direct steam cycle configuration improves heat transfer efficiency by removing intermediate heat exchangers. Passive safety systems operate without external power input, conserving energy during both normal operations and emergency scenarios. The compact core design, 20% smaller than conventional reactors, minimizes heat loss while maintaining the same power output of 1,500 MWe.

Cost Savings Over Time

The EPORBWR reduces operational expenses through several key design elements:

| Cost Reduction Factor | Savings Impact |

|---|---|

| Maintenance Requirements | 30% lower |

| Staffing Needs | 25% reduction |

| Fuel Usage | 15% more efficient |

| Plant Lifetime | 60 years vs 40 years |

The simplified plant layout eliminates 25% of valves pumps cables compared to traditional BWRs. Passive safety systems remove the need for multiple backup power sources reducing capital costs by 20%. The extended 60-year operational lifespan spreads initial investment costs over a longer period enhancing long-term economic viability.

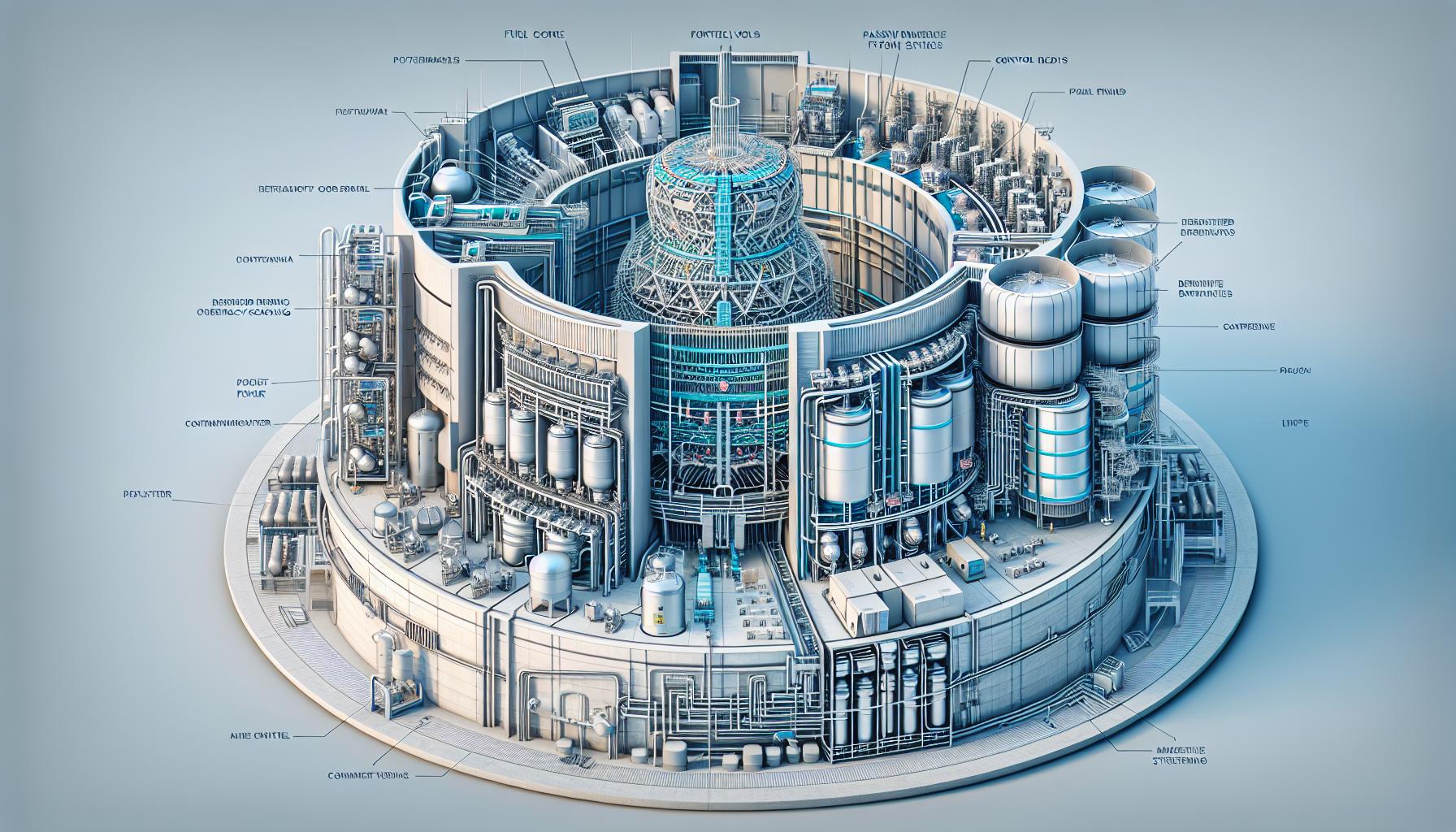

Main Components of an Eporbwr System

The EPORBWR system integrates advanced nuclear technology through specialized components designed for optimal performance and safety. These components work together to create a reliable and efficient power generation system.

Core Design Elements

The reactor core features a compact arrangement of fuel assemblies with advanced uranium dioxide pellets encased in zirconium alloy tubes. The core design incorporates 732 fuel bundles arranged in a cylindrical pattern, optimizing neutron efficiency and power distribution. Control rods made from boron carbide regulate the nuclear reaction through precise vertical positioning. The core shroud directs coolant flow while maintaining structural integrity at high temperatures. Steam separators above the core remove moisture from steam before it enters the power generation cycle.

Safety Features

The containment vessel incorporates multiple barriers including a reinforced concrete primary containment structure rated for 75 psig pressure. Passive safety systems operate through natural circulation using gravity-fed cooling pools located 20 meters above the core. Emergency core cooling systems activate automatically without electrical power through steam-driven injection pumps. The suppression pool absorbs excess energy during transient events through 16 main steam relief valves. An isolation condenser system removes decay heat for 72 hours without operator intervention.

Installation Requirements

An EPOR-BWR installation demands specific site conditions that meet nuclear regulatory standards. The facility location requires a minimum 100-acre plot with stable geological foundations capable of supporting a 250,000-ton structure.

Seismic qualification standards mandate:

- Ground acceleration tolerance of 0.3g horizontal peak

- Bedrock depth minimum of 30 meters

- Soil bearing capacity exceeding 400 kPa

Environmental prerequisites include:

- Access to cooling water source with 50,000 gallons per minute flow rate

- Maximum ambient temperature rating of 45°C

- Wind load resistance up to 150 mph

- Flood protection measures for water levels up to 30 feet

Infrastructure requirements encompass:

- High voltage transmission lines rated at 765 kV

- Backup power systems with 72-hour capacity

- Railway access within 5 kilometers

- Heavy haul road capability for 400-ton loads

| Technical Specification | Required Value |

|---|---|

| Site Area | 100 acres |

| Structure Weight | 250,000 tons |

| Cooling Water Flow | 50,000 gpm |

| Power Output Lines | 765 kV |

| Transport Road Rating | 400 tons |

Security infrastructure incorporates:

- Double perimeter fencing with 30-foot separation

- Advanced surveillance systems covering 360 degrees

- Radiation monitoring stations at 16 cardinal points

- Emergency response facilities within 10 minutes

These requirements align with international nuclear safety standards while maintaining the EPOR-BWR’s enhanced efficiency features.

Maintenance and Care Tips

Regular preventative maintenance ensures optimal EPOR-BWR performance through strategic inspection schedules. The primary circuits undergo inspection every 18 months during refueling outages.

Daily Monitoring Tasks:

- Check reactor coolant chemistry parameters

- Monitor containment pressure readings

- Record suppression pool temperature levels

- Verify natural circulation flow rates

- Inspect emergency cooling system status

Quarterly Maintenance Activities:

- Test passive safety system components

- Calibrate radiation monitoring equipment

- Clean heat exchanger surfaces

- Examine control rod drive mechanisms

- Service isolation condenser systems

Key maintenance protocols include testing the gravity-driven cooling system every 6 months. Operators examine fuel bundle assemblies during each 24-month cycle using ultrasonic testing methods.

- Replace boron carbide control rods after 15 years

- Conduct pressure vessel inspections every 10 years

- Update digital control systems every 5 years

- Service emergency power generators quarterly

- Replace neutron monitoring sensors biannually

The simplified design reduces maintenance costs through:

| Maintenance Aspect | Reduction % |

|---|---|

| Valve Count | 25% |

| Pump Systems | 30% |

| Cable Requirements | 20% |

| Labor Hours | 35% |

| Scheduled Outages | 15% |

Automated diagnostic systems monitor component performance continuously. Remote monitoring capabilities allow technicians to identify potential issues before they escalate.

The EPOR-BWR represents a significant leap forward in nuclear reactor technology combining enhanced safety passive systems with economic efficiency. Its innovative design reduces maintenance needs cuts operational costs and maximizes power output while maintaining the highest safety standards.

The reactor’s smart systems automated monitoring capabilities and simplified components make it a revolutionary advancement in nuclear power generation. With its impressive 60-year lifespan and reduced environmental impact the EPOR-BWR stands as a testament to the future of sustainable energy production.

The incorporation of advanced safety features stringent installation requirements and comprehensive maintenance protocols ensures that this next-generation reactor will continue to shape the landscape of nuclear energy for decades to come.